01

7 Jan 2019

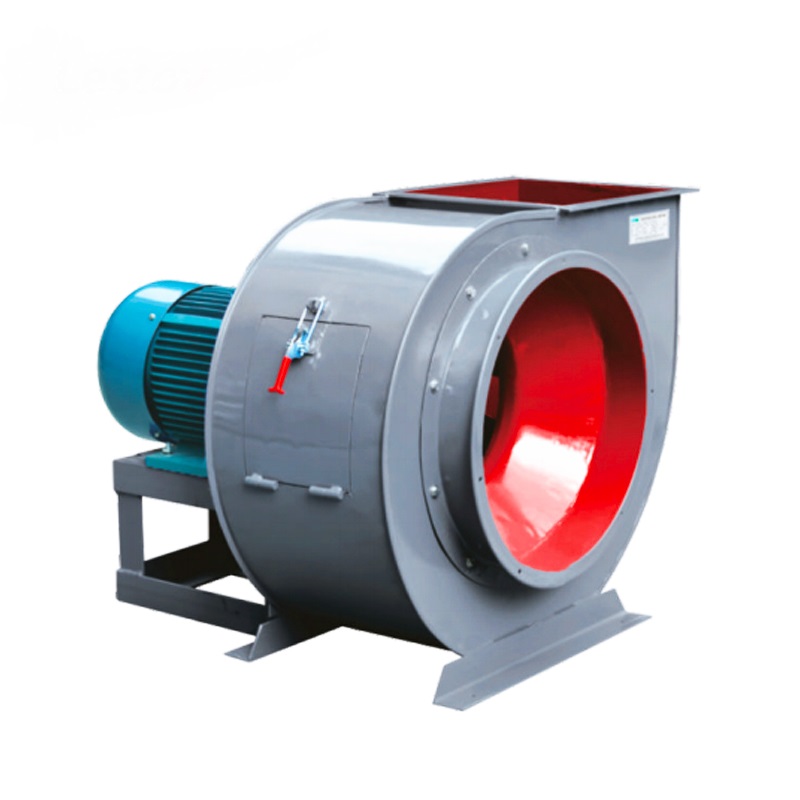

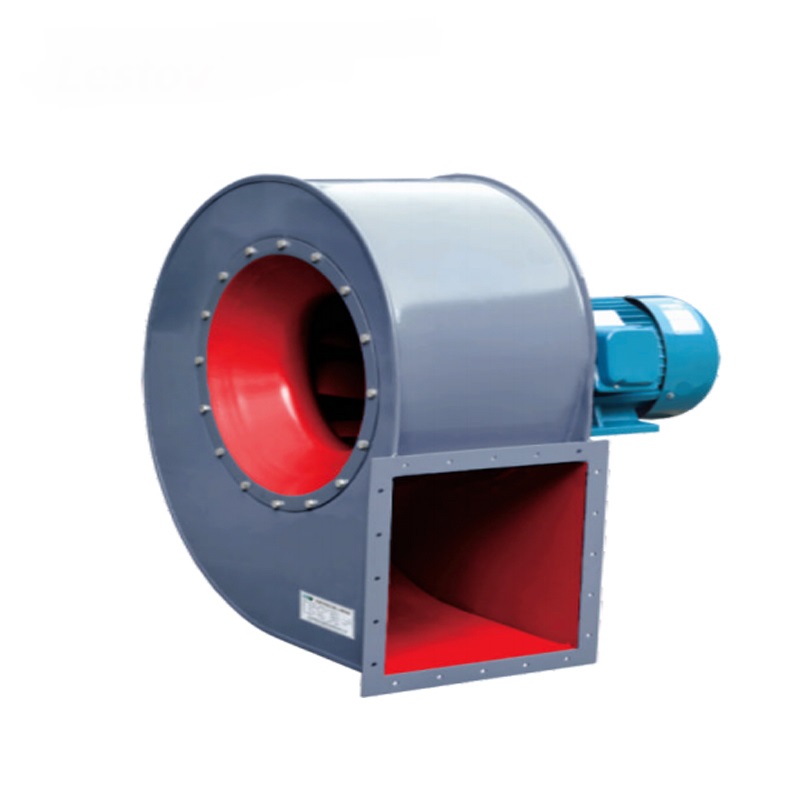

Use a backward-curved centrifugal impeller to capture and guide external airflow into the volute.

The high-speed rotation of the impeller generates centrifugal force, pushing the air toward the air outlets, exhaust ducts, or other ventilation systems.

The high-speed rotation of the impeller generates centrifugal force, pushing the air toward the air outlets, exhaust ducts, or other ventilation systems.

The excluded air flow creates a relatively low-pressure area, prompting more external air to enter the volute and achieving a continuous circulation of airflow.

02

7 Jan 2019

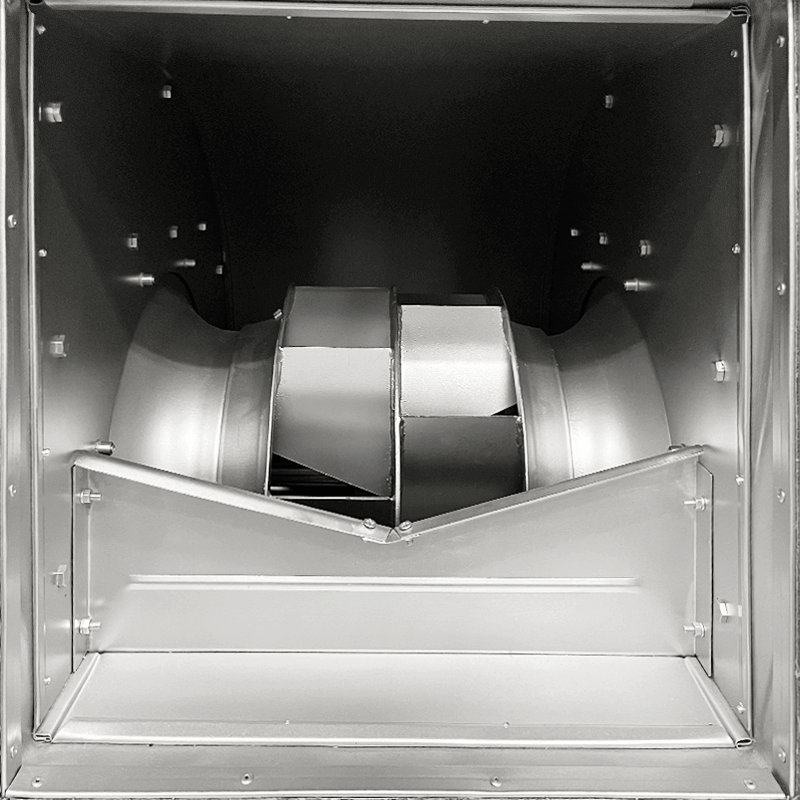

It adopts an all-stainless steel shell and structure, which is high-temperature resistant and can work stably under high-temperature conditions such as industrial drying or heat treatment; the stainless steel volute can effectively reduce noise.

03

7 Jan 2019

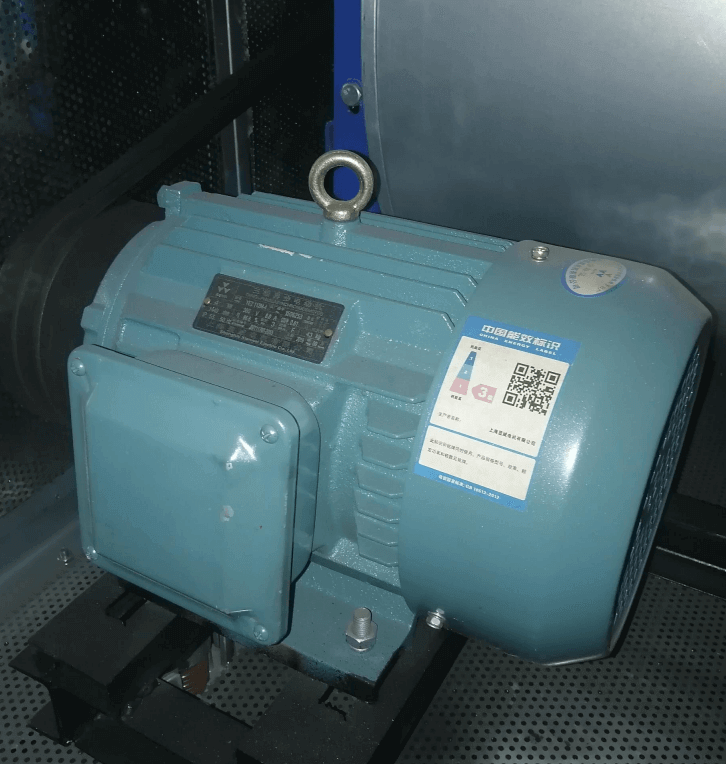

Using high-quality motors, the required power can be selected according to the fan's air volume, wind pressure, and operating conditions.

It drives the belt or rotating shaft to rotate efficiently and cooperates with the impeller to generate centrifugal force to absorb or discharge air.

04

7 Jan 2019

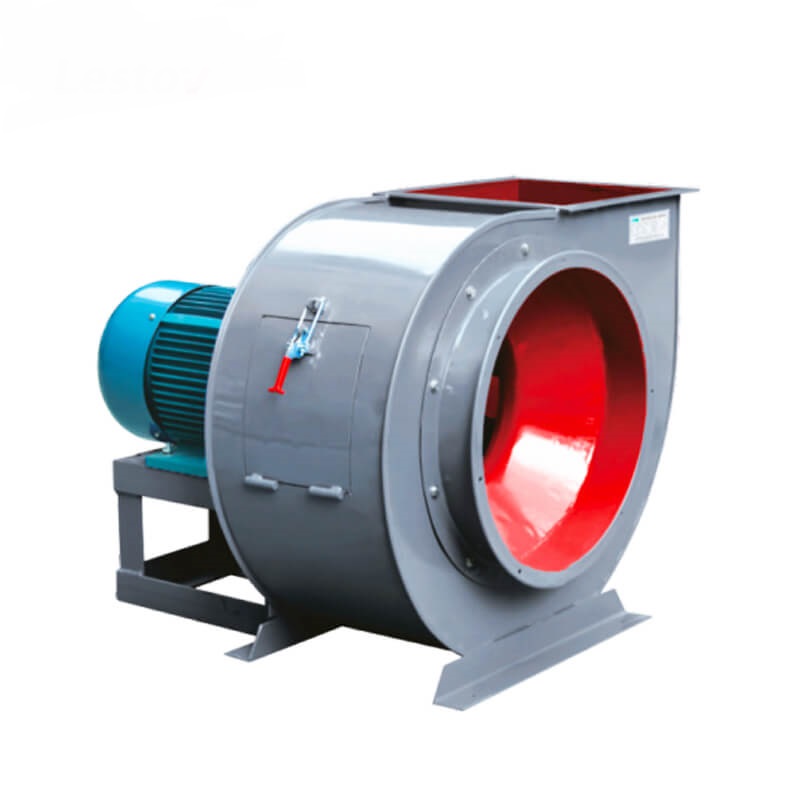

It can transport or discharge 4012m³ to 7419m³ of air per hour and is suitable for use with air supply or ventilation equipment,

Such as large factory purification equipment, civil buildings, large squares, generators, air treatment equipment, and hot air circulation systems.

Such as large factory purification equipment, civil buildings, large squares, generators, air treatment equipment, and hot air circulation systems.

PRODUCT VIDEO

Product Parameters

|

Model |

Size(mm) |

Air Flow (m³/h) |

Inlet Size(mm) |

Outlet Size(mm) |

Rotary Speed(r/min) |

Max Pressure(pa) |

Power / Voltage |

|

LF-4-72-4A |

L735*W800*H709 |

4012 to 7419 |

Φ400*443*480 |

W320*H280 |

2900 |

2014 to 1320 |

5.5KW / 380V |

|

2006 to 3700 |

1450 |

501 to 329 |

1.1KW / 380V |

Application

01

Canteen

2018-07-16

Lorem ipsum dolor sit amet consectetur adipisicing elit. Ex totam quod corporis reiciendis aliquam asperiores! Vel et sint maxime quae dolorem...

view detail

01

Factory

2018-07-16

Lorem ipsum dolor sit amet consectetur adipisicing elit. Ex totam quod corporis reiciendis aliquam asperiores! Vel et sint maxime quae dolorem...

view detail

01

Power plant

2018-07-16

Lorem ipsum dolor sit amet consectetur adipisicing elit. Ex totam quod corporis reiciendis aliquam asperiores! Vel et sint maxime quae dolorem...

view detail

01

Warehouse

2018-07-16

Lorem ipsum dolor sit amet consectetur adipisicing elit. Ex totam quod corporis reiciendis aliquam asperiores! Vel et sint maxime quae dolorem...

view detail

Leave Your Message

review

catalog download

Home

Home Commercial Ventilation Equipment

Commercial Ventilation Equipment Commercial Electrostatic Precipitator

Commercial Electrostatic Precipitator Commercial Kitchen ESP Hood

Commercial Kitchen ESP Hood UV Deodorate Purifier

UV Deodorate Purifier II Commercial Exhaust Hood

II Commercial Exhaust Hood Commercial ESP Range Hood

Commercial ESP Range Hood